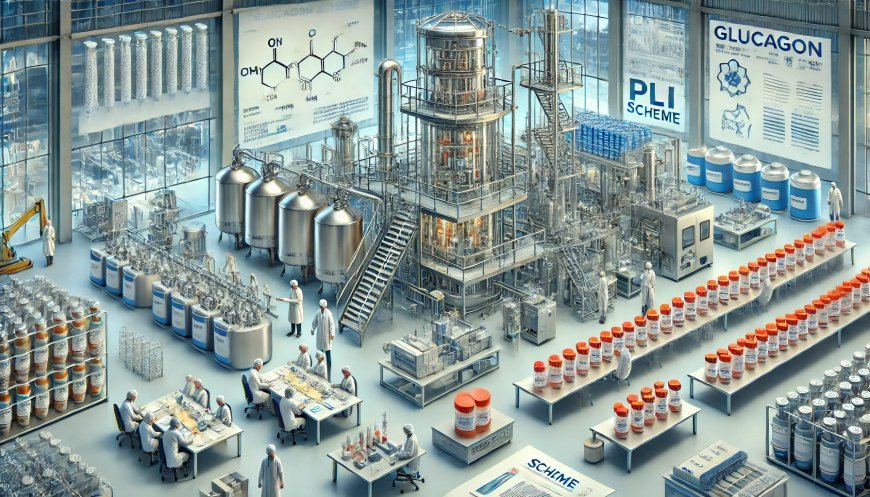

Glucagon Manufacturing in the Production Linked Incentive (PLI) Scheme: An Overview

The Production Linked Incentive (PLI) Scheme is a strategic initiative by the Government of India aimed at boosting domestic manufacturing and reducing import dependency in various sectors, including pharmaceuticals. One of the critical areas of focus under this scheme is the production of key active pharmaceutical ingredients (APIs) like glucagon. This article delves into the specifics of glucagon manufacturing within the framework of the PLI scheme, highlighting its significance, the manufacturing process, and the benefits provided by the scheme.

Significance of Glucagon

Glucagon is a vital peptide hormone produced by the pancreas that plays a crucial role in glucose metabolism. It is used in emergency treatment for severe hypoglycemia (low blood sugar) and is a critical component in managing diabetes. Given its importance in healthcare, ensuring a steady and cost-effective supply of high-quality glucagon is essential.

The PLI Scheme: An Overview

Launched by the Indian government, the PLI scheme aims to incentivize domestic companies to enhance their manufacturing capabilities. The scheme offers financial incentives based on incremental sales from products manufactured in domestic units. The goal is to create a robust manufacturing ecosystem, foster innovation, and generate employment.

Glucagon Manufacturing Under the PLI Scheme

-

Incentives and Support: The PLI scheme offers financial incentives to manufacturers of glucagon and other essential APIs. These incentives are designed to make domestic production economically viable and competitive with global manufacturers. Companies can receive benefits based on their incremental sales growth, helping offset the high costs associated with API production.

-

Infrastructure Development: The scheme encourages the establishment of state-of-the-art manufacturing facilities. Investments in modern infrastructure, including advanced biotechnological equipment and quality control labs, are critical for producing high-purity glucagon. The PLI scheme facilitates such investments through various subsidies and grants.

-

Research and Development: To ensure that India remains at the forefront of pharmaceutical innovation, the PLI scheme promotes research and development (R&D) in the field of API manufacturing. Companies are incentivized to invest in R&D activities to improve the production processes, enhance product quality, and develop new formulations of glucagon.

-

Regulatory Support: The Indian government provides regulatory support to streamline the approval process for new manufacturing units and products. This includes faster clearance times for manufacturing licenses, environmental clearances, and product approvals, reducing the time to market for new glucagon products.

Manufacturing Process of Glucagon

The production of glucagon involves several complex steps, including recombinant DNA technology, fermentation, purification, and formulation.

-

Recombinant DNA Technology: The initial step involves inserting the gene responsible for glucagon production into a suitable host organism, typically bacteria or yeast. This genetically modified organism is then cultured in bioreactors.

-

Fermentation: The cultured microorganisms undergo fermentation, where they multiply and produce glucagon. This step requires precise control of environmental conditions such as temperature, pH, and nutrient supply.

-

Purification: The crude glucagon produced during fermentation is then purified through various chromatographic techniques to remove impurities and ensure high purity and potency.

-

Formulation: The purified glucagon is formulated into a stable product, which may include lyophilization (freeze-drying) to enhance its shelf life. The final product is then packaged under sterile conditions for distribution.

Benefits of the PLI Scheme for Glucagon Manufacturing

-

Cost Reduction: By providing financial incentives, the PLI scheme helps reduce the overall cost of glucagon production, making it more affordable for domestic and international markets.

-

Enhanced Quality: Investments in modern manufacturing facilities and R&D lead to the production of high-quality glucagon that meets global standards.

-

Reduced Import Dependency: Increased domestic production of glucagon reduces reliance on imports, ensuring a stable supply and enhancing national healthcare security.

-

Employment Generation: The establishment of new manufacturing units creates job opportunities, contributing to economic growth and development.

Conclusion

The PLI scheme represents a significant step forward in bolstering India's pharmaceutical manufacturing capabilities. By focusing on essential APIs like glucagon, the scheme not only enhances the country's self-reliance but also positions India as a competitive player in the global pharmaceutical market. The incentives, infrastructure development, and regulatory support provided under the scheme are instrumental in achieving these goals, ensuring that high-quality glucagon is readily available for medical use.

What's Your Reaction?